Model EGLF-06A is a full automatic lip balm hot filling cooling production line designed for the production of lip balm and chapsticks. Working process: Auto loading empty tube into puck holder, auto 6 nozzles filling, precooling, reheating, cooling being solid, auto loading cap, auto pressing, auto separate tube from puck holder and discharge into labeling hopper, auto labeling.

1.Target Products

|  |  |  |

2.Descriptions

3.Specifications and Parameters

| Model No. | EGLF-06A |

| Output capacity | 55-60pcs/ min |

| Filling volume | 0-120ml |

| No. of nozzle | 6 |

| No. of operator | 1 |

| Tank volume | 50L/ set |

| Powder consumption | 12kw |

| Air put | 4-6kgf |

| Dimension(M) | 8.5×1.8×1.9 |

| Weight | 2500kgs |

4.Details

|  |  |  |

| Auto loading tubes into pucks | 6 nozzle feeding at same time | Precooling part | Reheating part |

|  |  |  |

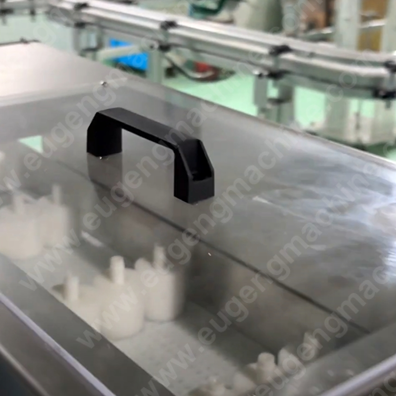

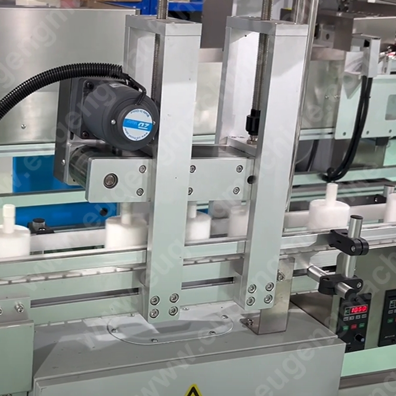

| Cooling tunnel | Cap feeder with vibrator | Auto loading cap | Auto pressing cap |

5.Reference video