Model EGMF-01A is an automatic rotary type filling and capping machine, specially designed for lip gloss and mascara production. Working process includes automatic loading empty tube into puck holder, automatic filling, automatic loading wiper, automatic pressing wiper, automatic wiper sendsor check, automatic loading brush and pre-capping, automatic servo control capping and automatic discharge finished product.

1.Target Products

|  |  |  |

2.Descriptions

3.Specifications and Parameters

| Model No. | EGMF-01A |

| Output capacity | 30-35pcs/ min |

| Filling volume | 0-50ml |

| No. of nozzle | 1 |

| No. of holder | 16 |

| No. of operator | 1-2 |

| Tank volume | 30L/ set |

| Powder consumption | 2.5kw |

| Air put | 4-6kgf |

| Dimension(M) | 2.3×1.4×1.75 |

| Weight | 350kgs |

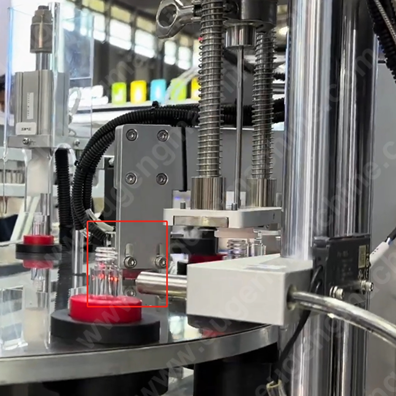

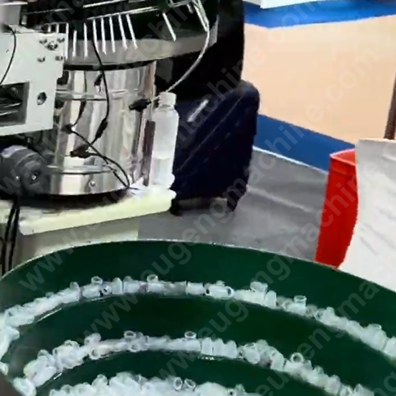

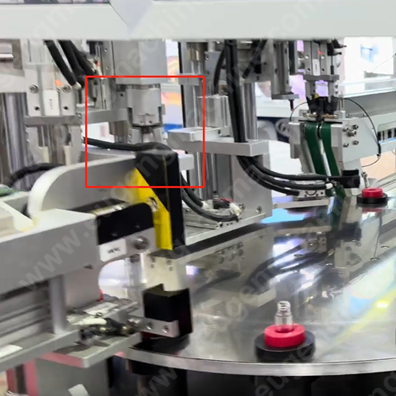

4.Details

|  |  |  |

| Feed empty tubes automaticly | Automatic filling, no tube no filling | Piston filling system | Automatic loading wiper |

|  |  |  |

| Automatic press wiper | Automatic loading cap | Automatic screwing cap | Automatic discharge finished products |

5.Reference video