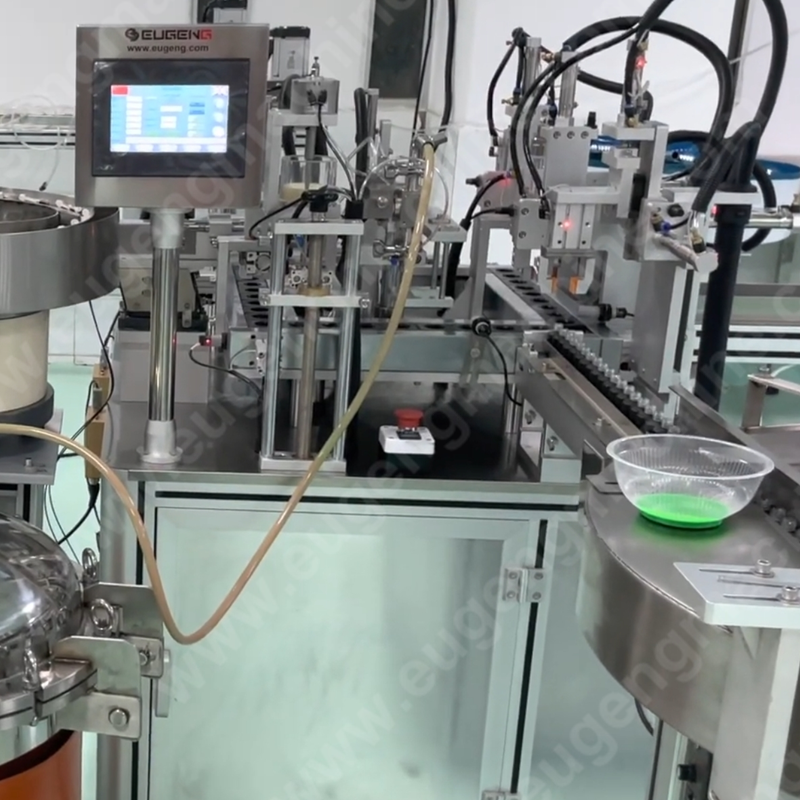

A nail polish filling machine plays a crucial role in modern production lines. These machines can fill bottles at impressive speeds, ranging from 20 to 80 bottles per minute. Advanced models push this limit further, reaching up to 120 bottles per minute. The speed depends on the machine's design and configuration. By automating the filling process, these machines ensure consistent output and reduce manual labor. Whether you manage a small-scale operation or a large production line, understanding the capabilities of these machines can help you optimize efficiency and meet your production goals.

Understanding BPM and factors influencing the speed of a nail polish filling machine

What is BPM (Bottles Per Minute)?

BPM, or Bottles Per Minute, measures how many bottles a machine can fill within one minute. This metric helps you evaluate the efficiency of a nail polish filling machine. A higher BPM indicates faster production, which is essential for meeting large-scale demands. However, the actual BPM depends on several factors, including the machine's design and the type of product being filled. Understanding BPM allows you to assess whether a machine aligns with your production goals.

Key factors affecting the speed of nail polish filling machines

Several factors influence how quickly a nail polish filling machine operates. Each plays a critical role in determining the overall efficiency of your production line.

Number of filling heads

The number of filling heads directly impacts the machine's speed. Machines with multiple filling heads can fill several bottles simultaneously, significantly increasing BPM. For example, a machine with four filling heads will fill four bottles at once, while a single-head machine processes one bottle at a time. If you aim to boost production, consider machines with more filling heads.

Viscosity of the nail polish

The thickness of the nail polish affects how quickly it flows into the bottles. Thicker formulas take longer to fill, reducing the machine's BPM. On the other hand, thinner nail polish flows more easily, allowing faster filling. Adjusting the machine's settings to match the viscosity of your product ensures smooth operation and consistent output.

Bottle size and shape

The size and shape of the bottles also influence the filling speed. Smaller bottles require less time to fill, while larger ones take longer. Unusual shapes may slow down the process because they need precise alignment to avoid spillage. Choosing bottles that are compatible with your machine can help maintain an efficient production pace.

Machine type (semi-automatic vs. automatic)

The type of machine you use plays a significant role in determining speed. Automatic machines operate faster because they handle multiple tasks, such as filling, capping, and bottle movement, without manual intervention. Semi-automatic machines require some manual input, which slows down the process. If speed is a priority, automatic machines are often the better choice.

Calculating the speed of a nail polish filling machine

Understanding how to calculate the speed of a nail polish filling machine is essential for optimizing your production line. By breaking down the process into manageable components, you can estimate the machine's efficiency and ensure it meets your production goals.

Components of the fill cycle

The fill cycle consists of three main steps: filling, capping, and bottle movement. Each step contributes to the overall speed of the machine.

Filling, capping, and bottle movement

The filling step involves dispensing the nail polish into the bottles. The machine's design and the viscosity of the nail polish determine how quickly this step occurs. Capping follows, where the machine places and secures caps on the filled bottles. This step requires precision to ensure proper sealing. Finally, bottle movement refers to the transfer of bottles through the machine. Smooth and efficient movement minimizes delays and keeps the production line running at an optimal pace.

Example calculation for estimating BPM

To estimate the Bottles Per Minute (BPM) of your machine, you need to consider the time taken for each step in the fill cycle. For example, if the filling step takes 2 seconds, capping takes 1 second, and bottle movement takes 1 second, the total cycle time for one bottle is 4 seconds. Divide 60 seconds by the cycle time to calculate the BPM:

Example Calculation:

Total cycle time = 4 seconds

BPM = 60 ÷ 4 = 15 bottles per minute

This calculation provides a baseline estimate. Machines with multiple filling heads or advanced automation can significantly increase this number.

Determining BPM based on production requirements

Your production requirements play a crucial role in determining the ideal BPM for your nail polish filling machine. Consider your daily output needs and the efficiency of your production line.

Daily output needs and efficiency considerations

Start by calculating how many bottles you need to produce each day. Divide this number by the total available production hours to determine the required BPM. For instance, if your goal is 7,200 bottles per day and your production line operates for 8 hours, you need a machine capable of filling 15 bottles per minute:

Example Calculation:

Daily output = 7,200 bottles

Production hours = 8 hours (480 minutes)

Required BPM = 7,200 ÷ 480 = 15 bottles per minute

Efficiency also matters. Machines rarely operate at 100% efficiency due to maintenance, setup, or unforeseen delays. Factor in a buffer to ensure your machine can handle the workload without compromising quality.

Choosing the right nail polish filling machine for your production line

Selecting the right nail polish filling machine is essential for achieving efficiency and meeting production goals. The choice depends on your production scale, budget, and operational needs. Understanding the differences between machine types and ensuring compatibility with your production line will help you make an informed decision.

Semi-automatic vs. automatic nail polish filling machines

When choosing between semi-automatic and automatic machines, you must consider their speed, cost, and functionality. Each type offers unique advantages depending on your production requirements.

Differences in speed, cost, and functionality

Semi-automatic machines require some manual input, such as placing bottles or initiating the filling process. These machines operate at a slower pace, making them suitable for small-scale production or businesses with limited budgets. They cost less than automatic machines and are easier to maintain. However, their reliance on manual labor can limit efficiency and increase the risk of inconsistencies.

Automatic machines, on the other hand, handle the entire filling process without manual intervention. They fill, cap, and move bottles seamlessly, achieving higher speeds and greater consistency. These machines are ideal for large-scale production lines where speed and precision are critical. Although they come with a higher upfront cost, their efficiency and ability to reduce labor expenses often justify the investment.

Tip: If your production volume is low, a semi-automatic machine may suffice. For high-demand operations, an automatic machine ensures faster output and better scalability.

Ensuring compatibility with other production line equipment

A nail polish filling machine must integrate smoothly with the rest of your production line. Proper compatibility prevents bottlenecks and ensures a steady workflow.

Avoiding bottlenecks and maintaining efficiency

Bottlenecks occur when one part of the production line operates slower than the rest, causing delays. To avoid this, ensure your filling machine matches the speed and capacity of other equipment, such as capping machines, conveyors, and labeling systems. For example, if your filling machine processes 80 bottles per minute but your capping machine handles only 60, the slower capping process will disrupt the workflow.

You should also consider the physical layout of your production line. Machines must align properly to allow smooth bottle movement. Regular maintenance and calibration further ensure that all equipment operates at peak efficiency.

Pro Tip: Before purchasing a filling machine, evaluate your entire production line. Identify potential bottlenecks and choose a machine that complements your existing setup.

A nail polish filling machine can transform your production process by delivering speeds between 20 and 120 BPM. Factors like machine type, product viscosity, and bottle size directly influence its performance. Calculating the required BPM ensures you select a machine that meets your production goals while maintaining efficiency. Whether you choose a semi-automatic or automatic model, the machine should align with your needs and integrate seamlessly with your existing equipment. Investing in a reliable filling machine not only boosts productivity but also ensures a smooth and consistent workflow for your business.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA