Introduction

In the food and beverage industry, hot filling machines are particularly important when a product needs to be filled with high temperature for better freshness as well as shelf life. Well, cleanliness and sanitation of this sort of machines are crucial processes to maintain product safety, quality and compliance with industry standards. We explain the procedure for keeping the hot filling machine shygenic from pre-operational sanitation to post-operational cleaning and maintenance in this content.

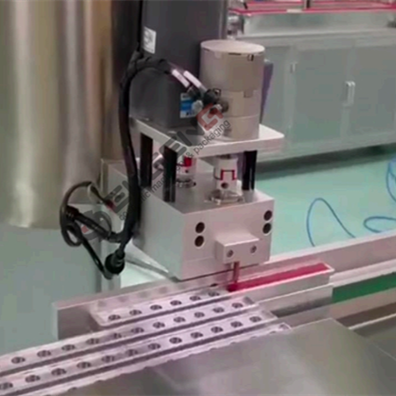

What are Hot Filling Machines

Hot filling machines offer high temperature product filling with immediate closure into a vacuum sealer. These are primarily used in sauces, soups, and drinks. Depending on the viscosity of the product, the machines can work using piston-type or peristaltic pumps. To successfully sanitize the machine, you need to know what its components are and how it works.

Pre-Operational Sanitation

It is important to set up a cleaning schedule and protocol before you start production, too. This means taking apart the machine to clean and sanitize every part that touches the product. Only approved solutions for sanitizing shall be used, and all traces of them removed. Periodic inspection of the machine parts can detect wear or damage and potential points where hygiene might be impacted.

Sanitation Practices within Operations

Altering action: Regular cleaning during production. That could mean sanitizing surfaces and confirming filling speeds and temperatures in accordance with the big industry players. It is also important to handle the containers and closures properly so as not to get them contaminated.

Cleaning And Sanitizing After Operations

Post production, you should make sure that a cleaning process is aligned. This involves completely taking apart the machine, washing all components, and placing them in a clean and dry place. As a result, documenting these cleaning procedures helps maintain consistency and provides a record that will be useful for the purpose of quality control inspection or regulatory audits.

Hot Filling Machine Wanna Outing?

Maintenance and Care of the Hot Filling Machine

Regular checks need to be carried out for maintenance so that the machine can work accurately and hygienically. This has been with lubricating and calibrating the filling levels, as well as temperatures. Preventative maintenance schedules schedule a periodic inspection of the machinery, which allows for identifying the harbinger of large-scale problems beforehand.

Environmental Controls

Hygienic depends on the environment where hot filling machine running. Watch the temperature and humidityGrow microorganisms. Pest control sanitation in general facility is also important. Regular checks and maintenance of air filtration and ventilation system.

Hygiene practices and Precisely Staff Training:

Putting staff through operating the machine and sanitation practices is essential. Good personal hygiene practices of operators (hand washing, use of gloves, etc.) on a farm can greatly minimize the chances of contamination. Routine Review and Update of Hygiene Procedures That Are Based on Best Practices

Quality Control and Assurance

The hot filling machine and process should undergo regular inspections and audits to ensure products are safe and of good quality. By analyzing for contaminants and/or residue, it can detect where the sanitation process has gone astray Programmes like HACCP (Hazard Analysis and Critical Control Points) provide a systematic approach for hygiene risk management.

Troubleshooting Common Sanitation Problems

It is important to recognize and fix sanitation issues quickly. Staff need to be aware of what corrective actions will be taken should there be a hygiene breach. This will help you avoid repeating the same issues in future production runs.

Compliance and regulatory breaches

Familiarity with the relevant industry standards and regulations for hygiene and sanitation is necessary. External validation of sanitation practices may also include certifications and audits for hygiene. Documentation and record keeping are also essential in terms of compliance with regulations as well as for quality assurance.

Conclusion

Hot Filling Machines Hygiene & Sanitation is required for the Quality & safety of products. If you can exercise systematic approach to cleaning, maintenance, environmental controls, staff training and regulatory compliance – you protect your products as well as the reputation of your brand.

Table of Contents

- Introduction

- What are Hot Filling Machines

- Pre-Operational Sanitation

- Sanitation Practices within Operations

- Cleaning And Sanitizing After Operations

- Hot Filling Machine Wanna Outing?

- Environmental Controls

- Quality Control and Assurance

- Troubleshooting Common Sanitation Problems

- Compliance and regulatory breaches

- Conclusion

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA