Mesin pengisi balm memberikan efisiensi yang mengesankan, dengan kecepatan pengisian tipikal berkisar antara 10 hingga 120 unit per menit. Jenis dan konfigurasi mesin memainkan peran penting dalam menentukan kecepatan ini. Model otomatis sering kali mengungguli model semi-otomatis, menawarkan hasil yang lebih cepat dan lebih konsisten. Volume produksi dan viskositas produk juga mempengaruhi pilihan peralatan. Bisnis harus dengan hati-hati mengevaluasi kebutuhan dan anggaran mereka untuk memilih mesin yang paling sesuai untuk operasi mereka.

Jenis-Jenis Mesin Pengisi Balm dan Kecepatan Pengisiannya

Mesin Pengisi Balm Semi-Otomatis

Mesin pengisi balsem semi-otomatis menawarkan solusi praktis untuk produksi skala kecil hingga menengah. Mesin ini biasanya mencapai kecepatan pengisian 10 hingga 30 unit per menit, tergantung pada model dan karakteristik produk. Operator memuat wadah secara manual dan memulai proses pengisian, sementara mesin menangani dispensi produk. Pengaturan ini memberikan kontrol yang lebih besar atas proses pengisian, menjadikannya ideal untuk bisnis yang memproduksi jumlah terbatas atau menangani produk dengan persyaratan viskositas yang unik.

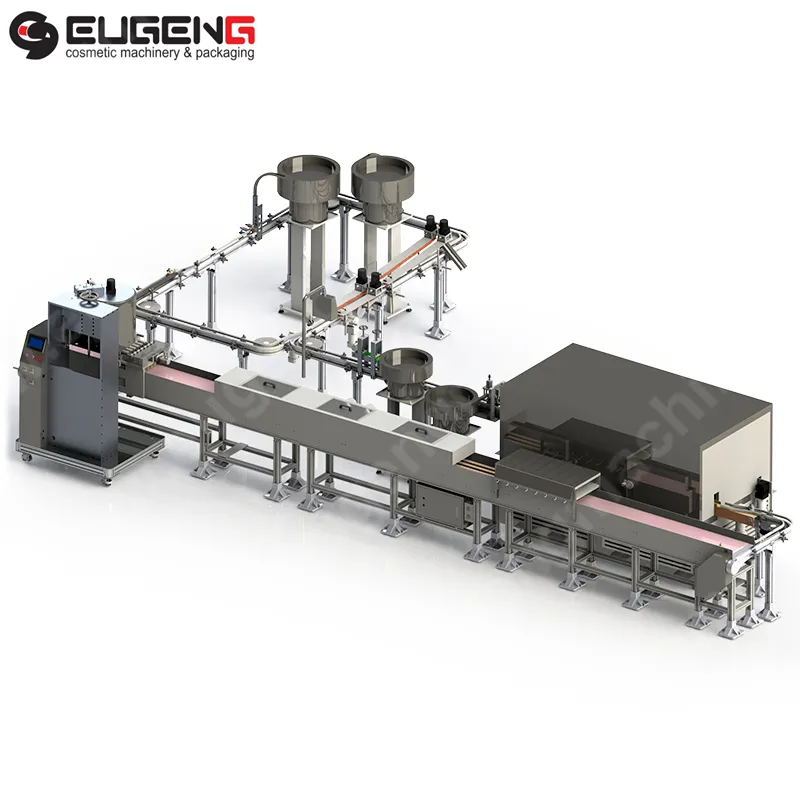

Mesin Pengisi Balsem Sepenuhnya Otomatis

Mesin pengisi balsem otomatis sepenuhnya memenuhi kebutuhan produksi volume tinggi. Mesin ini beroperasi pada kecepatan pengisian yang berkisar antara 30 hingga 120 unit per menit, tergantung pada konfigurasi dan jumlah kepala pengisian. Mereka mengotomatiskan seluruh proses, dari pemuatan wadah hingga dispensi produk dan penyegelan, meminimalkan intervensi manusia. Tingkat otomatisasi ini memastikan presisi dan konsistensi, bahkan selama operasi skala besar.

Mesin Pengisian Multi-Kepala

Mesin pengisian multi-kepala secara signifikan meningkatkan kecepatan pengisian dengan memungkinkan beberapa wadah diisi secara bersamaan. Mesin ini dapat memiliki dua, empat, atau bahkan lebih banyak kepala pengisian, tergantung pada kebutuhan produksi. Misalnya, mesin dengan empat kepala dapat mencapai kecepatan pengisian hingga 120 unit per menit, karena mengisi empat wadah dalam satu siklus. Desain ini mengoptimalkan efisiensi dan mengurangi waktu produksi.

Faktor yang Mempengaruhi Kecepatan Pengisian

Jumlah kepala pengisian

Jumlah kepala pengisian secara langsung mempengaruhi kecepatan pengisian mesin pengisian balsem. Mesin kepala tunggal mengisi satu wadah pada satu waktu, menjadikannya cocok untuk produksi skala kecil. Mesin ini biasanya beroperasi pada kecepatan yang lebih lambat, sering kali berkisar antara 10 hingga 30 unit per menit. Bisnis dengan permintaan produksi terbatas atau yang memprioritaskan presisi daripada volume sering memilih sistem kepala tunggal.

Mesin multi-kepala, di sisi lain, secara signifikan meningkatkan efisiensi. Dengan mengisi beberapa wadah secara bersamaan, mereka mencapai kecepatan yang lebih tinggi, kadang-kadang melebihi 120 unit per menit. Misalnya, mesin empat kepala dapat mengisi empat wadah dalam satu siklus, secara drastis mengurangi waktu produksi. Kemampuan ini menjadikan sistem multi-kepala ideal untuk operasi volume tinggi. Perusahaan yang bertujuan untuk memenuhi target produksi skala besar sangat diuntungkan dari mesin ini, karena mereka mempertahankan konsistensi sambil meningkatkan output.

Viskositas dan Konsistensi Produk

Viskositas dan konsistensi produk memainkan peran penting dalam menentukan kecepatan pengisian. Balm atau krim yang lebih kental memerlukan lebih banyak waktu untuk dikeluarkan, yang dapat memperlambat proses. Mesin yang dirancang untuk produk dengan viskositas tinggi sering kali dilengkapi dengan pompa khusus atau mekanisme pemanas untuk memastikan pengisian yang lancar dan akurat. Fitur-fitur ini membantu menjaga efisiensi meskipun ada tantangan yang ditimbulkan oleh formulasi yang lebih kental.

Produk dengan viskositas rendah, seperti balm cair, mengalir lebih mudah dan memungkinkan kecepatan pengisian yang lebih cepat. Namun, penyesuaian pada pengaturan mesin mungkin masih diperlukan untuk mencegah tumpahan atau pengisian berlebih. Operator harus dengan hati-hati mengkalibrasi peralatan agar sesuai dengan karakteristik produk. Penyesuaian yang tepat memastikan bahwa mesin beroperasi pada kecepatan optimal tanpa mengorbankan akurasi atau kualitas.

Tipe Mesin dan Tingkat Otomatisasi

Jenis mesin dan tingkat otomatisasinya secara signifikan mempengaruhi kecepatan pengisian. Mesin manual sepenuhnya bergantung pada operasi manusia, yang mengakibatkan kecepatan yang lebih lambat. Mesin ini paling cocok untuk produksi skala kecil atau bisnis kerajinan di mana presisi dan kontrol lebih diutamakan daripada volume.

Mesin semi-otomatis menawarkan keseimbangan antara kontrol manual dan otomatisasi. Mereka biasanya mencapai kecepatan berkisar antara 10 hingga 30 unit per menit, tergantung pada model dan produk. Operator menangani tugas seperti penempatan wadah, sementara mesin mengotomatiskan proses pengisian. Pengaturan ini memberikan efisiensi sedang dan ideal untuk produksi skala menengah.

Mesin otomatis sepenuhnya memberikan kecepatan pengisian tertinggi, sering kali berkisar antara 30 hingga 120 unit per menit. Mesin ini mengotomatiskan setiap langkah proses, mulai dari pemuatan wadah hingga penyegelan. Teknologi canggih mereka memastikan kinerja yang konsisten, menjadikannya sangat penting untuk operasi skala besar. Bisnis yang fokus pada memaksimalkan output dan meminimalkan biaya tenaga kerja sering kali berinvestasi dalam sistem otomatis sepenuhnya.

Mesin pengisian balm memberikan kecepatan pengisian berkisar antara 10 hingga 120 unit per menit. Jenis mesin, viskositas produk, dan tingkat otomatisasi secara signifikan mempengaruhi kinerja ini. Bisnis harus mengevaluasi kebutuhan produksi mereka, anggaran, dan tujuan jangka panjang untuk membuat keputusan yang tepat. Memilih mesin yang tepat meningkatkan efisiensi operasional, meminimalkan waktu henti, dan memastikan kualitas produk yang konsisten. Berinvestasi dalam mesin pengisian balm yang sesuai tidak hanya mengoptimalkan produksi tetapi juga mendukung skalabilitas dan profitabilitas di pasar yang kompetitif.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA