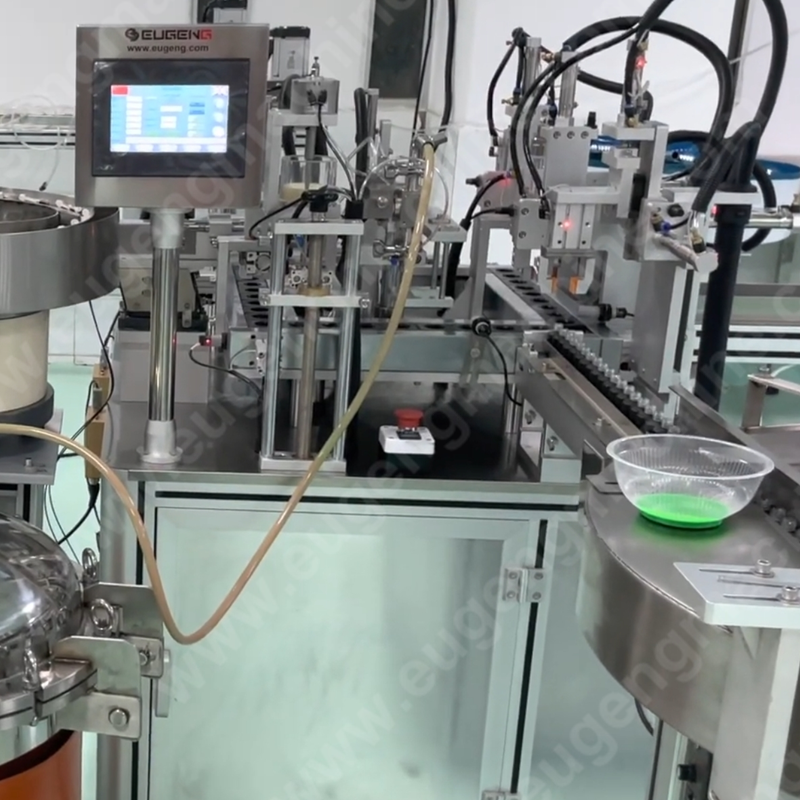

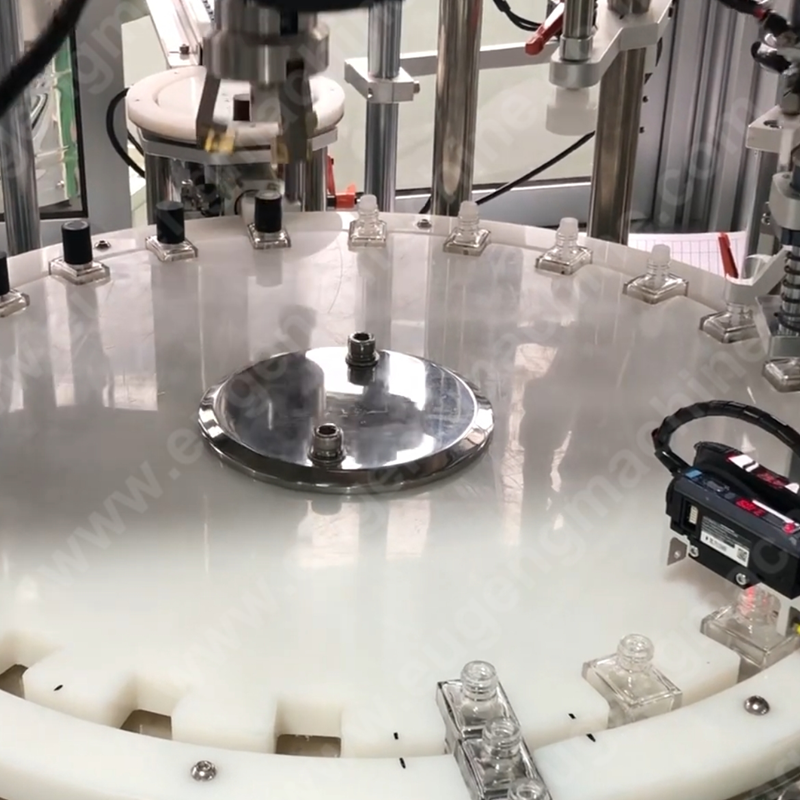

A nail polish filling machine plays a crucial role in modern production lines. These machines can fill bottles at impressive speeds, ranging from 20 to 80 bottles per minute. Advanced models push this limit further, reaching up to 120 bottles per min...

VIEW MORE

Introduction One of the most essential factors of nail lacquer viscosity that impacts filling speed and accuracy. Density liquid is high viscous nature pose serious challenge for filling equipment, due to scale precision doser relative power with mat...

VIEW MORE

Nail polish filling machines work best with specific container types. These include glass, plastic, and metal options. Using the right containers ensures smooth operations and reduces waste. It also helps maintain the quality of your nail polish. Cho...

VIEW MORE

Introduction A nail polish filling machine works with so much efficiency and precision, determining how productive a cosmetics production line can be and to what level its quality will be. It will also ensure that you are getting the best performance...

VIEW MORE

Introduction In the garment business, production processes need to be productive and exact. However, the right equipment can make a difference in output quality and operational costs when it comes to filling nail polish bottles. The following guide i...

VIEW MORE

Introduction Though the cosmetic industry is one that moves rapidly; one constant, particularly for consumers willing to pay anything for a quality product, is Nail Polish Fill is Key. Nail polish filling machine is a crucial machine as it helps in k...

VIEW MORE

Introduction Energy efficiency: in this era where environmental concerns and economic sustainability go together, the choice of machinery with high energy efficiency is crucial. However, when packaging fresh foods or hot filling beverages, this prese...

VIEW MORE

Introduction Technology has long been developed to hot fill, with hot filling machines essential in many industries for this purpose, particularly across food and beverage where filling at high temperatures helps maintain the sterilization and life o...

VIEW MORE

Introduction They are used in the food and beverage industries where when containers pass through it they are filled, generally a hot product then capped closing the package to preserve the contents. This makes the product sterile and prolongs shelf ...

VIEW MORE

Introduction Greater efficiency in production is crucial in the food and beverage industry, in view of its highly competitive nature. Hot filling machines caters for the huge technology that helps in speeding up tillages and further enriches producti...

VIEW MORE

Introduction For products that require aseptic packaging, hot filling machines are vital machinery in the food and beverage industry. These machines fill containers with hot product then clip or screw them shut to maintain sterility and the product's...

VIEW MORE

Introduction The hot filling machines have a major role to play when it comes to fulfilling various processes on the food and beverage industry as they are specifically designed to fill products such as sauces, soups, beverages etc. Sanitization of t...

VIEW MORE