Model EGNF-01A is nail polish filling and capping machine is a full automatic rotary type nail polish machine designed for the production of nail polish, gel polish. The entire process is automatic feeding bottles, filling balls, loading brush, loading cap and capping.

1.Target Products

|  |  |  |

2.Descriptions

1 set of 60L pressure tank

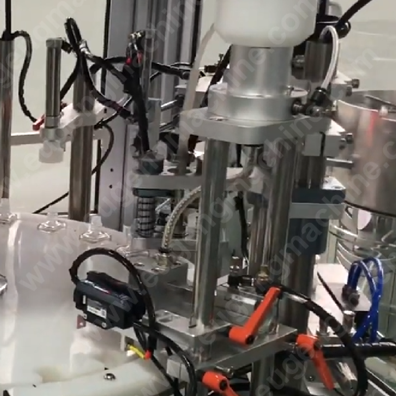

Automatic feeding bottles, filling balls, loading brush, loading cap and capping

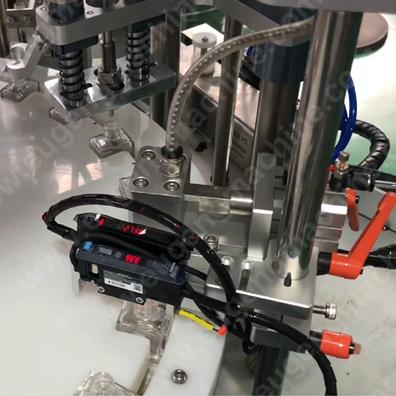

1 set of filling balls unit with automatic by cylinder, and fill 0 / 1 / 2 balls once

Piston filling structure for optional

If material with more big glitter, suggest use piston filling system

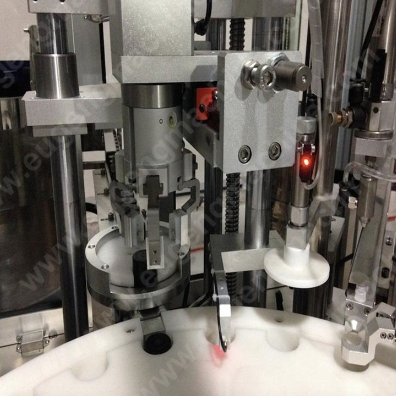

Cap tightening station tightens caps to correct torque by servo motor( you can set the torque through touch screen)

Automatic taking out the finished products

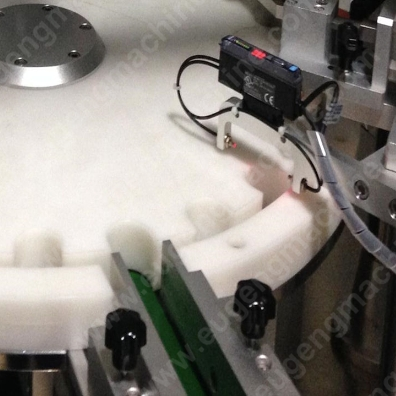

This mold use Nylon pucks( according To different bottle size)

This voltage is 220V 50Hz

3.Specifications and Parameters

| Model No. | EGNF-02A |

| Output capacity | 30pcs/ min |

| Filling volume | 0-30ml |

| No. of nozzle | 1 |

| No. of operator | 0 |

| Tank volume | 60L/ set |

| Powder consumption | 4kw |

| Air put | 4-6kgf |

| Dimension(M) | 2.3×2.3×1.5 |

| Weight | 450kgs |

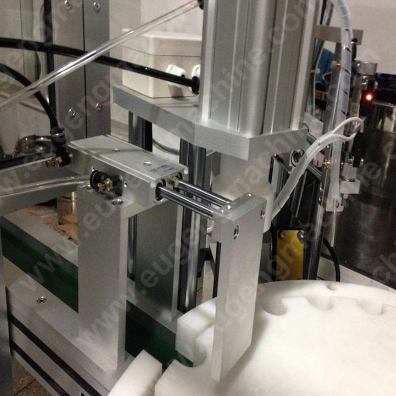

4.Details

|  |  |  |

| Automatic feeding bottles | Conveyor feed bottle into machine | Sensor check, no bottle no filling | Automatic feeding ball |

|  |  |  |

| Filling nozzle with guider | Auto loading brush and pressing | Screw capping, torque can be adjusted | Automatic take out the finished products |

5.Reference video