1.Target Products

2.Descriptions

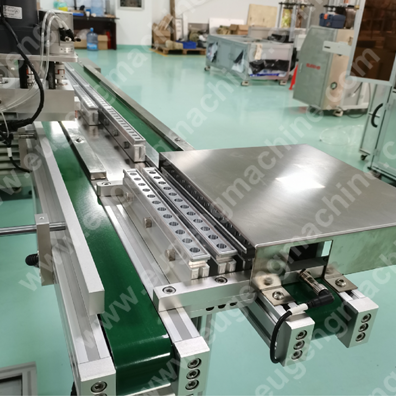

Mold pre-heating with touch heating plate

1 set of 3 layers of jacketed vessels 25L capacity with mixer Tank with automatic pre-heating system from Monday to Sunday, time can be adjustable Servo motor filling system with high Accuracy +/-0.3% Filling volume and filling speed controlled by digital input, and filling volume and speed can be adjustable Filling unit designed for easy strip-down cleaning and re-assembly to facilitate quick change over Automatic frost remove prevent water on the mold, defrost cycle time is adjustable Temp control by digital T.I.C, and Min is -20 centigrade Temperature accuracy is +-2 centigrade

Stainless steel 304 frame, and spray foam in frame for preventing water dipping at the door

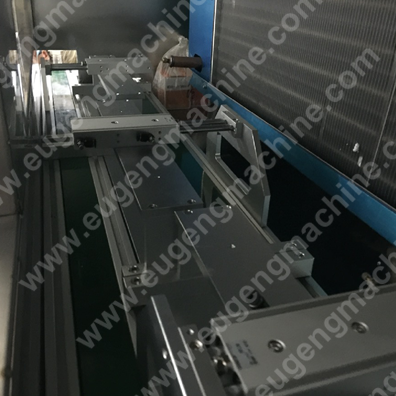

Semi-automatic releasing, taking out the top mold by hand with tooling, and then put a guid mold for help put empty tubes with straight way Put the mold into semi-automatic releasing machine for insert lipstick into case Two button pressing designing for protect operator safe Releasing area have air blowing from aluminum mold

Options Extra gear pump Lipstick filling mold Lipstick releasing tooling 3.Specifications and Parameters

Model No. EGLF-1A Output capacity 36-48pcs/ min Filling system Servo motor for new machine No. of nozzle 1 No. of operator 2-3 Tank volume 25L/ set Powder consumption 5kw Air put 4-6kgf Dimension(M) 5×1.1×1.75 Weight 600kgs

4.Details

Mold preheating Servo motor filling system 25L tank with heating and mixing Mixing speed adjustable Filling volume adjustable Cooling tunner machine Releasing machine The finished lipstick

5.Reference video