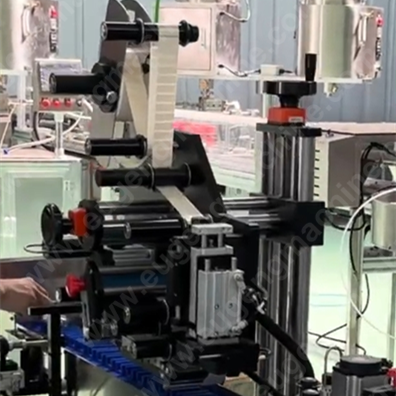

Model EGBL-500 tube bottom and lody labeling machine is an semi-automatic labeling machine, designed for the labeling of bottom and body, such as lip balm bottles, lipstick bottles, mascara, eyeliner pen, glue stick and so on.

1.Target Products

|  |  |  |

2.Descriptions

3.Specifications and Parameters

| Model No. | EGBL-500 |

| Production type | Liner type |

| Output capacity/hr | 1200-2400pcs/ hour |

| Control type | Servo motor |

| Labeling accuracy | +-1mm |

| Product size range | 9mm≤Diameter≤30mm, Length≤140mm |

| Label size range | Bottom label: D≤20mm, Side label: 10≤W≤25mm, 10≤L≤80mm |

| No. of operator | 1 |

| Display | PLC |

| Powder consumption | 2.5kw |

| Dimension(M) | 3.5×1.3×1.7 |

| Weight | 260kgs |

4.Details

|  |  |  |

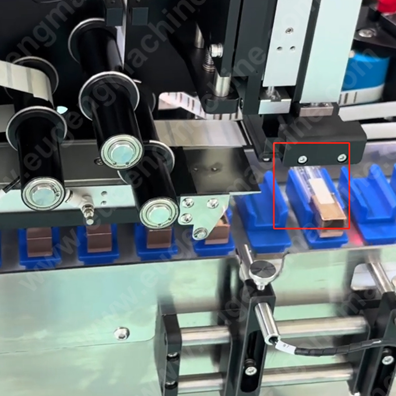

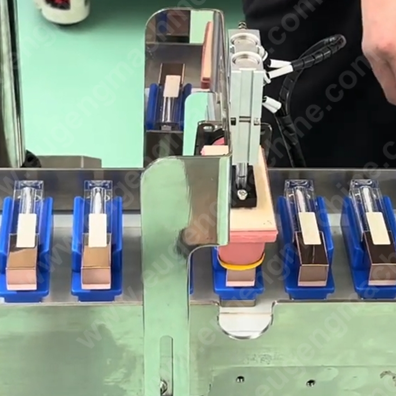

| Checking tube position | Body label unit | Label on the body | Press body label tighten |

|  |  |  |

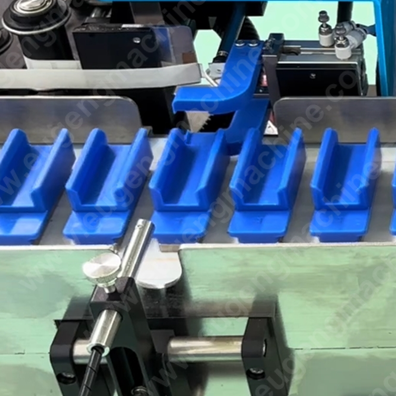

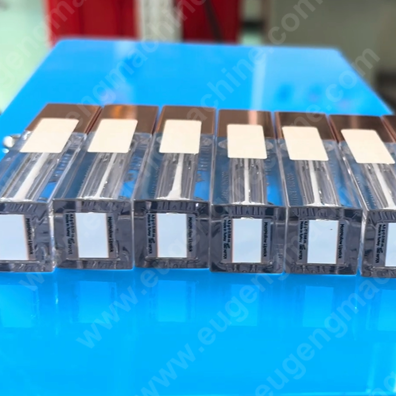

| Sensor check the bottle | Label on the bottom | Auto discharge | Finished products |

5.Reference video