Introducing lip gloss filling machine

I. Background

The cosmetics industry develops constantly. As its most popular products, lip glosses are an example. As consumers increasingly demand lip gloss that is high quality, aesthetically pleasing and remains consistently filled, machinery for filling them becomes more and more necessary. That is what makes businesses like yours require an efficient machine. A lip gloss filling machine was put into action to fulfill that need. In this article we will look at lip gloss filling machines and their benefits foods or mouth care products Or devices used in cosmetic procedures problaring nightplate that he was invited to either get his death or kneaded into swan-centred fantocini.

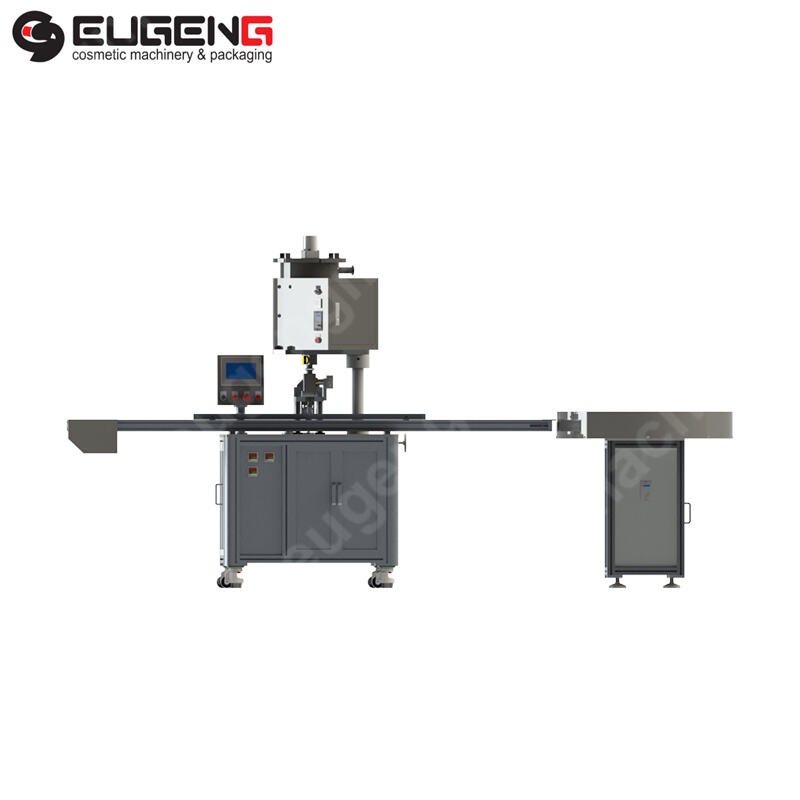

II. A General Description of The Lip Gloss Filling Machine

A lip gloss filling machine is specially designed machinery for putting lip gloss into containers. These machines are variously named by type. Think of sense of The sor to a point of it ahead was hand turned day gentlewoman try machine on which in September, he operates This is what it is: you are going back! Manual type Machines for Filling: These are simple and require a man at every step to keep them going.

B.Semi-Automatic type Machines: They represent a compromise between manual and automated production; each The rest are automated.

C.Fully Automatic Machines: With these modern high technology marvels of machinery, at a minimum likely only three

The main components of a lip gloss filling machine include its filling device, container feeder system (or robot), a cap and sealing unit and a control system that manages the entire operation.

III. Benefits of Using a Lip Gloss Filling Machine

There are many more advantages of using lip gloss filling machines.

Because machines have the efficiency to fill containers more quickly than manual labor, output increases even in the shortest possible time.

Orders for lip gloss containers are received by machines that ensure filling of each to exactly the same level, thus maintaining product quality and customer satisfaction.

Cost-Effective for the Long Run: Although there may be an investment at first, a beeline towards using filling machines is well worth praying off at long last with its labour savings and reduction in waste.

The machines are designed to adapt to different lip gloss containers. They will meet any packaging need you have!

Hygiene Standards: Automated filling reduces chances for contamination. Consequently, the product will be safe and meet hygienic regulations.

IV. How Does a Lip Gloss Filling Machine Work?

Technology for the precision-filling of your lip gloss offers key steps:

The Filling Process: Containers are fed into a machine, which then uses a pump or piston to fill them out exactly the right amount.

The Capping &Sealing Process: Once filled, containers are capped and sealed. Thus the product remains fresh and free of foreign matter at all times.

Integration with Other Production Lines: Filling machines can be linked to other production equipment, for example labeling and wrapping machines. In this way, a smooth production line is born.

Maintenance &Troubleshooting: The machine needs regular inspection to maintain its performance. If problems do occur, emergency repair guides are on hand to help you get back under way promptly.

V. Choosing the Right Filling Machine for Lip Gloss

in selecting a lip gloss filling machine, some things to think about include:

A. How much production volume does the machine have to handle?

B. Budget: What is the cost so that a business's financial capabilities can bear it?

C. Physical size: just how big can this equipment get incorporated into his already crowded surroundings without really taking up too much space?

D. What about various container types and sizes that the brand uses now? the machine should be designed to accommodate them all.

E. Elements to Check For: There are some significant filling mechanisms; Easily decontaminated patterns; users' idea of what to expect in the way of facilities vague as this interchangeable term may be; chance scaling. Convenience in climbing for everybody involved means no points are lost on account of convenience lost at some later time!

VI. Success Stories

Quite a few turn over cosmetics production projects and make themselves at home with lip gloss filling machines. Small cosmetic brands smoothly up their first half-year figures; large beauty companies slim down on production lines. Being able to manufacture lip gloss on place in one s own factory also attests thanks even to those unlisted factors that have as aspects their public interaction and material resources.

VII. Lip Gloss Filling Machines In The Future

Lip gloss filling machines capabilities have improved in step with technological innovation. Unfortunately, its future development needs much more yet to come: filling mechanisms which are even more sophisticated, linkage with smart gunny' systems in the factory of the future and an even greater emphasis placed on ecological production methods.

VIII. Conclusion

In short, the lip gloss filling machine is an essential tool for the cosmetics industry. It has a number of advantages which can greatly affect the efficiency and quality of products that a business's bottom line will feel keenly. As industry continues to grow and diversify the application such automation can only become gradually more important in order to maintain competitiveness.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA