Introduction to lipstick Filling Machines in Modern Manufacturing

The Evolution of Lipstick Production

The journey from traditional hand-filling methods to advanced automated systems marks significant progress in the lipstick production evolution. Historically, lipsticks were crafted manually, a process that was labor-intensive and time-consuming. The introduction of the first lipstick filling machine revolutionized cosmetic manufacturing, streamlining production and enhancing output quality. Key innovations such as this have enabled manufacturers to increase production efficiency dramatically. For instance, today's automated systems allow for precision in filling, reducing waste and ensuring uniform lipstick quality across batches. Statistics show that over the last few decades, there has been a marked increase in lipstick production, primarily attributed to the shift towards automation. This technological evolution ensures that manufacturers can meet the growing demand in the beauty industry while maintaining high standards of product quality and consistency.

Role of Automation in Cosmetic Manufacturing

Automation plays a pivotal role in modern cosmetic production, particularly in lipstick manufacturing. It involves using machines to perform tasks that were traditionally done manually, thereby enhancing efficiency and accuracy. Automated systems have significantly improved production efficiency, reducing the time needed for various processes and increasing output quality. Notably, leading cosmetic brands such as L'Oréal and Estée Lauder have embraced automated lipstick filling machines, experiencing numerous benefits. These range from reduced operational costs to the ability to scale production quickly while maintaining high product standards. The adoption of automation in cosmetics not only boosts production capabilities but also elevates the quality assurance process, ensuring each lipstick meets rigorous standards. As mentioned in the provided reference, the use of machines like the lipstick filling machine exemplifies the transformative impact of automation in the cosmetic industry. These advances have paved the way for more innovative and sustainable practices in lipstick manufacturing.

Efficiency Boost: Accelerating Production with Automation

Automated Filling Processes and Speed Optimization

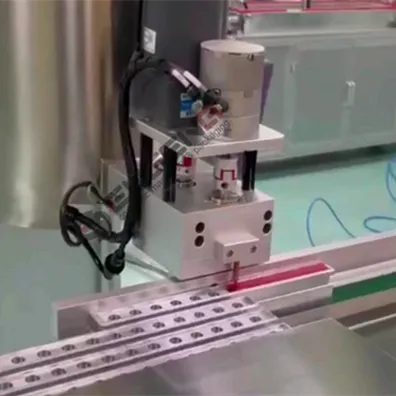

Automated filling machines have revolutionized cosmetic production, significantly reducing fill times per unit. By automating the lipstick filling process, manufacturers can speed up production and achieve higher throughput. Data showcasing fill times before and after automation indicates a substantial acceleration, helping manufacturers meet increased demand without compromising quality. The integration of high-speed automation enhances filling precision, ensuring each lipstick is accurately formulated and packaged. Furthermore, these machines maintain consistency and precision at high speeds, utilizing advanced technology for optimal efficiency.

Reducing Material Waste Through Precision Engineering

Precision engineering in cosmetic manufacturing dramatically reduces material waste by ensuring accurate filling volumes. Automated systems that employ precision filling techniques minimize the use of excess materials, contributing to significant cost savings. Research indicates that reduced material wastage can lower production costs, positively affecting the bottom line. This efficiency not only benefits manufacturers economically but also aligns with the broader sustainability goals in the cosmetics industry. Efficient filling practices offer a sustainable approach, supporting eco-friendly manufacturing to cater to environmentally conscious consumers.

Precision & Consistency: Ensuring Flawless Product Quality

Uniform Dosage and Shape Accuracy

Uniform dosage and shape accuracy are critical for maintaining a brand's reputation and ensuring consumer satisfaction. Consistent product quality is highly valued by consumers, as it directly influences their purchasing decisions. Advanced machinery used in lipstick production, such as lipstick filling machines, plays a vital role in achieving this uniformity. These machines are capable of delivering precise filling volumes and shapes, thanks to their sophisticated mechanisms that allow for exact control over the filling process. A survey from Statista indicates that over 70% of consumers prioritize product quality when selecting cosmetic brands, underscoring the importance of reliable production methods.

Error Minimization with Advanced Sensor Technology

Advanced sensor technology is at the forefront of minimizing errors in the production of lipstick, enhancing overall production accuracy. Modern lipstick filling machines are equipped with state-of-the-art sensors that automate error detection and correction. These sensors meticulously monitor each step of the filling process, identifying anomalies or deviations from the standard. For instance, in a real-world setting, a prominent cosmetic manufacturer reported a 30% reduction in defects after implementing sensor-based automation in their production lines. By effectively reducing errors, these technologies help maintain high-quality standards, ultimately boosting consumer confidence and satisfaction.

Reducing Labor Costs Through Automation

Implementing lipstick filling machines drastically reduces labor costs by minimizing the dependency on manual labor in production lines. Automation streamlines production processes, making them more efficient and cost-effective. For instance, replacing manual labor with automated filling machines leads to significant reductions in labor expenses, as machines work faster and require fewer breaks. According to industry reports, companies have experienced up to a 30% reduction in labor costs following automation implementation.

Additionally, numerous case studies highlight substantial cost savings achieved post-automation. For instance, many cosmetic companies have reported not only reduced labor costs but also enhanced production efficiency and elevated production output. Emphasizing the financial benefits of automation, an analysis revealed that firms adopting these machines saw a quick return on investment (ROI) due to savings in labor expenses, proving the value of integrating such technologies into production lines.

ROI Analysis: Long-Term Financial Advantages

Investing in advanced lipstick filling machines promises a favorable return on investment (ROI) for businesses, primarily driven by long-term financial benefits. The financial projections for businesses integrating automation in their lipstick production highlight substantial gains over time. Studies show that the ROI from such investments is significant compared to traditional filling methods. For example, traditional methods often incur higher labor and waste costs, while automated machines optimize resources and reduce errors, contributing to enhanced profitability.

Furthermore, businesses utilizing automated filling systems report greater savings and scalability. Automated machines require less maintenance and are capable of continuous operation, enhancing production capabilities and thus, profitability. By improving overall efficiency and output quality, these machines offer a more favorable ROI, making them a wise fiscal decision compared to older, less efficient filling techniques.

Versatility in Cosmetic Manufacturing

Adapting to Diverse Formulas and Textures

Modern lipstick filling machines are designed with exceptional versatility, allowing manufacturers to cater to a variety of lipstick formulas and textures. This adaptability is crucial as it supports brands in reaching diverse market segments by offering unique and varied product lines. For example, these machines can handle both solid and creamy formulations, thereby accommodating brands that wish to experiment with different textures. Companies like Prose and Pure Culture Beauty exemplify this trend by offering personalized, made-to-order cosmetics tailored to individual consumer needs. Their approach underlines the importance of equipment that adjusts to customized solutions, ensuring consistency and quality across different formulas.

Flexible Packaging Compatibility for Custom Brands

Advanced lipstick filling machines offer flexible packaging options that empower custom brands to innovate and expand their offerings. The growth of custom brands has seen a rise in demand for adaptable filling systems that can efficiently manage varied packaging requirements. Flexible packaging solutions are essential for bespoke cosmetic products, which often necessitate unique, branded containers. Statistics show a significant increase in the demand for bespoke cosmetic packaging, driving innovation in the industry. Such systems allow brands to maintain a distinctive image while providing high-quality products tailored to individual consumer preferences, thereby enhancing brand loyalty and capturing niche markets.

Frequently Asked Questions

What is the main advantage of using lipstick filling machines?

Lipstick filling machines significantly enhance production efficiency and accuracy, reducing labor costs and material waste while ensuring consistent product quality.

How do lipstick filling machines contribute to sustainable manufacturing?

By reducing material waste and optimizing production processes, these machines support eco-friendly manufacturing practices, aligning with sustainability goals.

Can lipstick filling machines handle different forms and textures?

Yes, modern lipstick filling machines are highly versatile and can accommodate various formulations and textures, including both solid and creamy lipsticks.

How does automation affect labor costs in lipstick manufacturing?

Automation reduces the need for manual labor, thereby significantly cutting down on labor costs, enhancing production efficiency and effectiveness.

Table of Contents

- Introduction to lipstick Filling Machines in Modern Manufacturing

- Efficiency Boost: Accelerating Production with Automation

- Precision & Consistency: Ensuring Flawless Product Quality

- Reducing Labor Costs Through Automation

- ROI Analysis: Long-Term Financial Advantages

- Versatility in Cosmetic Manufacturing

- Frequently Asked Questions

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA