Introduction to Lip Gloss Filling Machine Lifespan

Overview of Lip Gloss Filling Machines

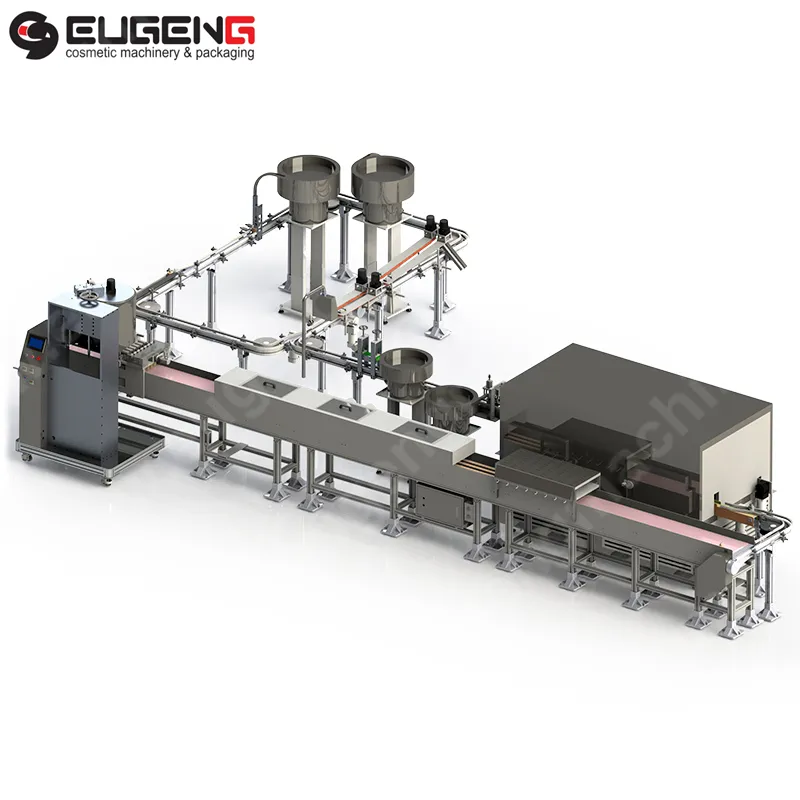

Lip gloss filling machines play a crucial role in the cosmetics industry by providing an efficient method for packaging products. These machines are designed to fill liquid, semi-solid, or viscous lip gloss into various tube types, ensuring consistency and quality in production. Lip gloss filling machines come in different types, including semi-automatic and fully automatic options. Semi-automatic machines require manual input, whereas fully automatic machines offer streamlined operations with minimal human intervention. The use of lip gloss filling machines not only enhances quality control but also boosts the efficiency of production lines, allowing manufacturers to meet the growing demand for cosmetic products.

Why Lifespan and Maintenance Matter

The lifespan of lip gloss filling machines is a critical factor for manufacturers as it impacts cost efficiency and production sustainability. A longer lifespan means fewer replacements and reduced maintenance costs, translating into monetary savings. Regular maintenance helps uphold safety standards and ensures the quality of the output, which is of paramount importance in the cosmetic industry. Proper upkeep of machines not only guarantees compliance with industry regulations but also minimizes downtime, leading to more consistent production. By extending the lifespan of machinery through diligent maintenance, businesses can significantly improve their profitability, ensuring a stable and efficient production environment.

Typical Lifespan Expectancy of Lip Gloss Filling Machines

Average Lifespan Range (5-10 Years)

The average lifespan of a lip gloss filling machine typically falls between 5 to 10 years. This duration varies based on factors like the frequency of use and the quality of regular maintenance performed. Machines subjected to consistent maintenance can extend beyond this average, ensuring longer operational life and reliability. Evidence from industry surveys often reflects this range, showcasing how manufacturers expect these machines to perform under standard conditions. Moreover, the adherence to preventive maintenance, as recommended by manufacturers, plays a crucial role in maximizing this lifespan and avoiding unnecessary downtimes.

High-Quality vs. Budget Machine Longevity

When considering the longevity of lip gloss filling machines, high-quality models generally outperform budget options. While the initial investment might be higher for premium machines, they often offer longer operational life and reduced maintenance costs over time. This is because high-quality machines are built with reliable components and advanced technologies, translating into greater durability and stability. Conversely, budget machines may incur frequent repairs and replacements. Data from industry experts consistently show a noticeable difference in lifespan, with high-quality machines far surpassing their budget counterparts in terms of reliability and longevity. This realization encourages businesses to weigh upfront costs against long-term savings and efficiency.

Key Factors Influencing Machine Longevity

Usage Frequency and Production Volume

Usage frequency and production volume play critical roles in determining the lifespan of lip gloss filling machines. Increased usage can accelerate wear and tear, inevitably affecting the machine's longevity. For instance, machines running continuously under high-demand conditions tend to experience faster degradation compared to those operating at moderate levels. Additionally, the production volume directly influences the stress levels experienced by these machines. A higher production volume can lead to increased mechanical strain, thereby shortening the service life. Statistically, there is a noticeable correlation between the frequency of machine usage and maintenance costs, where frequent use often results in greater maintenance needs and expenses. Understanding these dynamics is crucial for optimizing machine performance and lifecycle.

Product Viscosity and Formula Compatibility

The variances in lip gloss viscosities significantly impact machine operation and longevity. Different viscosities can alter the flow dynamics, potentially causing strain if not aligned with machine specifications. Formula compatibility ensures that the product components do not react adversely with machine parts, thereby preventing damage. Case studies have highlighted longevity issues linked to using incompatible products, where machines faced premature degradation due to mismatched formulas. Ensuring that the lip gloss's consistency and composition are compatible with the machine's design is vital for maintaining efficiency and extending operational life. Properly matching these elements can lead to smoother operations and fewer maintenance disruptions.

Environmental Conditions and Operational Stress

Environmental conditions such as temperature and humidity are integral in influencing lip gloss filling machines' performance. Extreme temperatures can cause components to expand or contract, leading to mechanical failures over time. Similarly, high humidity levels can facilitate rusting and corrosion. Operational stress, including rapid cycling and frequent stops, causes additional strain on mechanical parts, reducing their lifespan. To mitigate these factors, adopting best practices like maintaining a stable, controlled environment and ensuring smooth machine operations can be beneficial. Recommendations include establishing protective measures like temperature regulation and routine inspections to alleviate stresses, ensuring the longevity and reliability of filling machines.

The Role of Regular Maintenance in Extending Lifespan

Scheduled Cleaning to Prevent Residue Buildup

Scheduled cleaning is crucial for maintaining lip gloss tube filler machines and preventing residue buildup. Residue can severely affect machine efficiency and compromise product quality. Therefore, implementing regular cleaning regimens is imperative. By adhering to recommended cleaning frequencies and methods, manufacturers can ensure that machines operate at optimal efficiency, reducing the risk of contamination and mechanical failures. These schedules should be based on usage intensity and available guidelines to mitigate residue-related issues effectively.

Lubrication and Part Replacement Cycles

Lubrication plays a vital role in minimizing friction within lip gloss tube filler machines, thereby extending their lifespan. Regular lubrication reduces wear on moving parts, leading to smoother operation and enhanced performance. Additionally, certain machine parts require periodic replacement due to wear and tear. Identifying these critical components and adhering to timely replacement schedules is essential for maintaining machine efficiency. These strategic maintenance cycles not only prevent unexpected breakdowns but also optimize the machine's functionality.

Calibration and Software Updates

Periodic calibration is necessary for maintaining the filling accuracy of lip gloss tube filler machines. Ensuring precise calibration prevents inconsistencies in product filling, which is vital for maintaining manufacturing quality. Moreover, software updates are crucial for modern machines, enhancing productivity and adding new functionalities. Neglecting calibration and software updates can lead to decreased machine longevity and impair operational efficiency. Incorporating these maintenance aspects routinely helps in sustaining the performance and extending the lifespan of the equipment.

Signs of Aging & When to Replace

Increased Downtime or Frequent Repairs

Increased downtime and frequent repairs are primary indicators of an aging machine. Such interruptions not only disrupt production schedules but also escalate maintenance costs. Businesses should conduct regular analysis of repair logs to determine if the costs of repairs are becoming prohibitive. When the cost of maintaining equipment exceeds the benefits, it might be time for a complete replacement. Case studies in industrial settings often highlight how companies that fail to address frequent repairs experience increased operational costs and decreased productivity. By understanding these warning signs, businesses can make informed decisions about when it may be more cost-effective to replace aging machinery.

Declining Filling Accuracy or Speed

A decline in filling accuracy or operational speed can signal the onset of machine aging. Precision is crucial, especially with equipment like lip gloss filling machines, where accuracy impacts product quality and customer satisfaction. Maintaining speed is essential to meet production demands and maintain competitiveness. Statistical evidence supports that dips in accuracy often correlate with decreased operational efficiency, thereby affecting overall output. When machines can't maintain their designed speed and scale of production, it may be time to consider replacements that offer enhanced capabilities and reliability.

Obsolescence Due to New Industry Standards

As technology advances, older machines can become obsolete, especially when they fail to meet new industry standards. This obsolescence impacts compliance and competitiveness within the market. For instance, updated regulations or advancements in production technology can render older models ineffective or non-compliant. Companies must evaluate whether investing in retrofitting older machines or replacing them altogether would be more beneficial. The decision should consider current industry benchmarks and potential improvements in efficiency and productivity that new machinery may offer. By staying aligned with industry standards, businesses can ensure continued compliance and optimal performance.

faq Section

What is the average lifespan of a lip gloss filling machine?

The average lifespan typically ranges between 5 to 10 years, depending on factors like frequency of use and maintenance quality.

How does regular maintenance impact machine longevity?

Regular maintenance extends the machine's lifespan by ensuring optimal performance, reducing wear and tear, and preventing breakdowns.

Are high-quality machines worth the investment?

Yes, high-quality machines often provide longer operational life and lower maintenance costs, making them a cost-effective choice over time.

What are signs that a machine needs replacement?

Signs include increased downtime, frequent repairs, declining accuracy or speed, and failing to meet new industry standards.

Table of Contents

- Introduction to Lip Gloss Filling Machine Lifespan

- Typical Lifespan Expectancy of Lip Gloss Filling Machines

- Key Factors Influencing Machine Longevity

- The Role of Regular Maintenance in Extending Lifespan

-

Signs of Aging & When to Replace

- Increased Downtime or Frequent Repairs

- Declining Filling Accuracy or Speed

- Obsolescence Due to New Industry Standards

- What is the average lifespan of a lip gloss filling machine?

- How does regular maintenance impact machine longevity?

- Are high-quality machines worth the investment?

- What are signs that a machine needs replacement?

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA