What is a hot filling machine and how does it work?

Introduction

In the food and beverage packaging world, the hot filling machine works like a guardian of freshness, using heat to seal in quality and extend shelf life. This article delves deeply into the domain of hot filling machines, exploring their structure and applications, as well as discussing benefits that this kind of equipment can bring to packaging industry.

The Process of Hot Filling

Hot filling is an aseptic process that inactivates pathogens by heating, then produces a vacuum package to seal the heated product away from its environment. In doing so, refrigeration and preservatives are needed no longer – this method can keep goods fresher for longer than any other.

Components of a Hot Filling Machine

The hot filling machine is an elegant assemblage of a number of components that combine to maintain the quality of the product. Among them are:

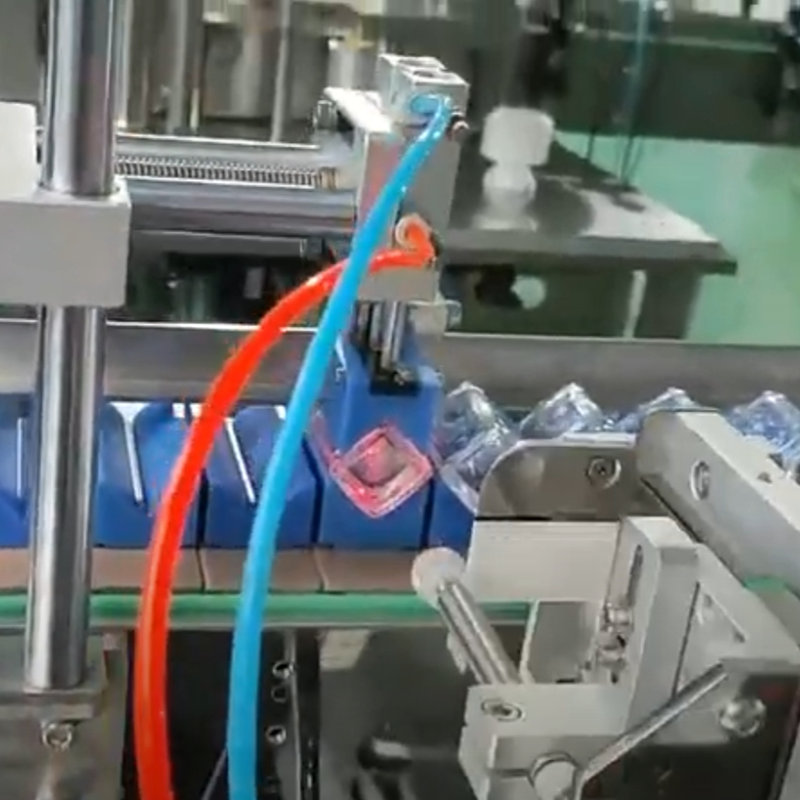

The container feeding mechanism, which ensures that containers are transported in a stable flow to the filler.

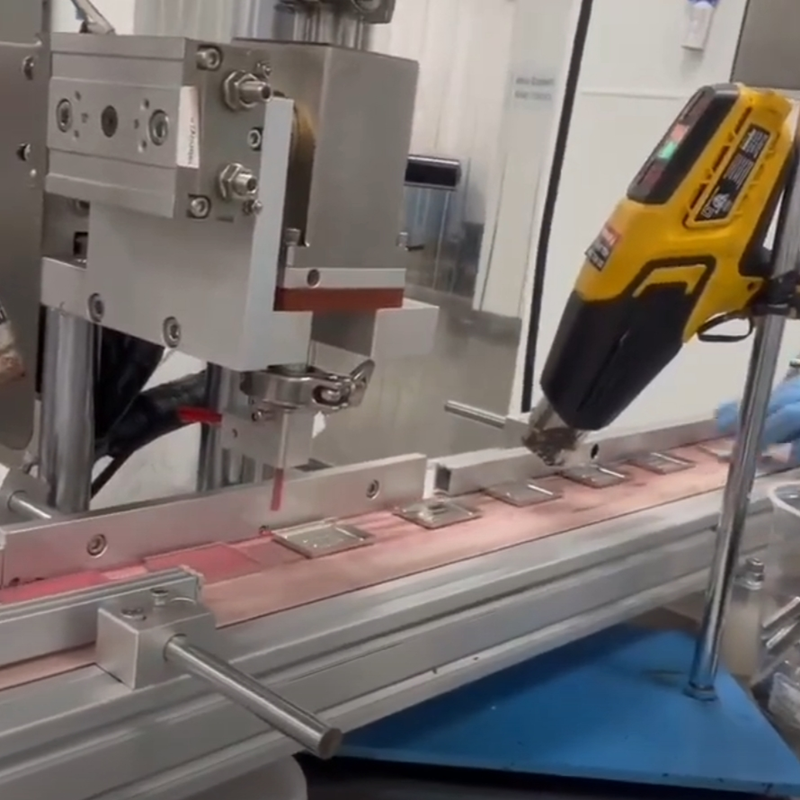

Filling nozzles and valves transport the hot product evenly into containers. In this way, an evenly filled package is created.

The package sealing and capping unit gives absolute sterility to containers.

A conveyor system transports containers through the machine.

Temperature control and monitoring systems ensure absolute precision of heat delivery.

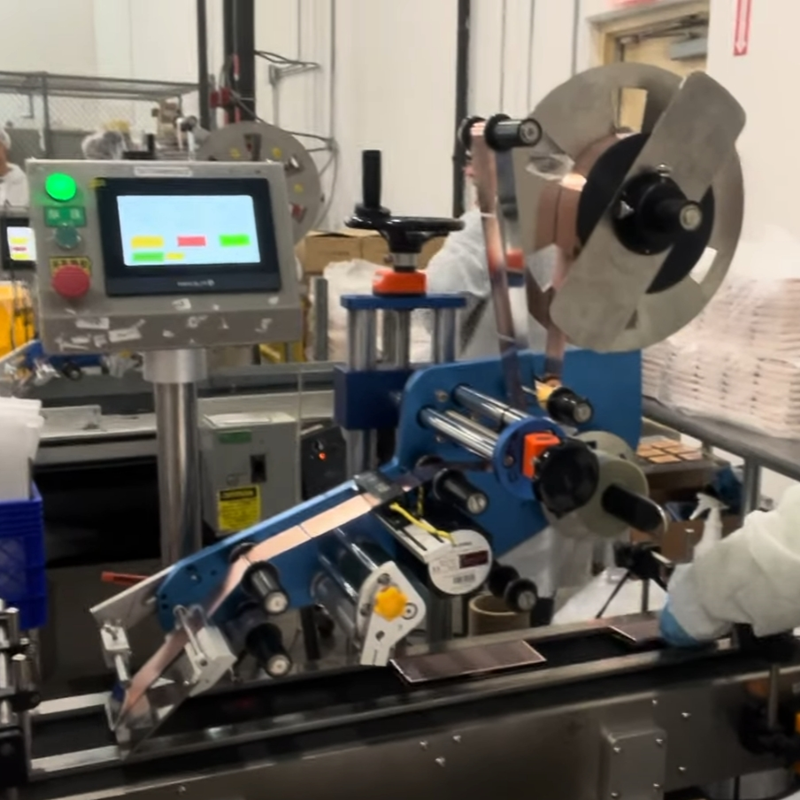

A control panel and user interface enable operators to manage their equipment functions.

How hot filling machine works

The process begins with products prepared to the highest temperature. The product can typically be as hot as 85°C (185°F), depending on what it is actually cooked at. Hot sterilized containers are filled with boiling products and sealed straight away in order to eliminate all air; a vacuum is thereby created. In some cases, the sealed containers are cooled so that material will contract still more and the seal becomes stronger. Then it's time to eject the filled and sealed containers--ready for packaging and labeling--once they'vebeen sufficiently cooled down.

Types of hot filling machines

Hot filling machines serve various production scales and needs: Manual hot filling machines, for small-scale operations or low-production volume products Semi-automatic machines, providing a balance between automaton and manual control at the press of a button, which offers more flexibility Fully automatic hot filling machines designed for high-volume lines where speed is all-important and efficiency guaranteed

Applications of hot filling machines

The versatility of hot filling machines suits them to a wide variety of manufacturers. Hot filling is used in fats and sauces, fruit juices, jellies among food and beverages-- The pharmaceutical industry uses hot filling to manufacture hot liquid medicines--nichards, nutritional valuables Some lotions and creams benefit by an aseptic packaging process even though they are packed with hot material for packaging. The cosmetic industry also uses hot filling for these items.

Advantages of using hot filling machine

Hot filling machines possess several advantages that make them indispensable for any packaging line: They extend the shelf life of a product without adding preservatives, satisfying consumer demand for natural and healthy products It combines heat treatment of the largest bacterium so as to protect your safety agains toxic pathogens (bacteria) With straight sealing immediately after filling, there is no contamination risk at all To save power, some models are designed for higher efficiency operation costs run low

Challenges and Issues

Despite their advantages, hot-filling machines pose a number of problems.

To remain sanitary and ensure that products are not poisoned by foul substances or bacteria, you must maintain the machine and clean it regularly.

The machine may be devoted to specific container size and type markets and have a limited compatiblity.

Energy consumption is a problem, although modern machines are increasingly turning to energy saving technologies.

Maintenance and Repair

This means that a great deal of regular maintenance is essential for optimal performance of hot filling machines. This involves cleaning the machine after every production run, and checking for worn seals and moving parts. In addition, to ensure accurate dispensing the filler mechanism must be calibrated.Assuming no serious mechanical or electrical faults you can usually solve such common difficulties as leakage or incorrect filling through simple checks and adjustments.

Future Trend of Hot Fill Technology

In future hotbox filling technology looks set for further boost with developments in autoisation, energy-saving and the integration of Industry 4..0 of Industry 4.. These new ideas are going to help even more to round off the characteristics of hot-box filling machines, such as general performance level and safety and economy.

Conclusion

Hot filling machines show what can be done through technological innovation in ensuring the safety and quality of one's ware. Once we reflect on its influence with regard to the shelf life of products and the health of consumers, it is not an exaggeration to say that this should not be forgotten. As technology continues to advance, hot filling machines will remain at the forefront in packaging solutions, ensuring that our everyday commodities remain just as fresh-tasting and aromatic the day they were made.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR UK

UK VI

VI HU

HU TH

TH TR

TR FA

FA MS

MS UR

UR BN

BN LO

LO LA

LA PA

PA